With the pressure to avoid any disruption to rail operations, an inspection team in the Netherlands turned to the Elios 3 drone to inspect the roof of a train station. This innovative approach not only saved time but also ensured safety and efficiency during the process. Access The unique structure of the train station made it nearly impossible for inspectors to reach the roof safely. Traditional methods would require scheduling train downtime up to 13 weeks in advance. Instead, the Elios 3 was used to gather data during nighttime hours, avoiding any disruption to regular services. No Downtime By conducting inspections at night with the Elios 3, the NS Stations team avoided any disruptions to rail traffic. This meant no changes to public transport schedules. Previously, such work would have required closing three train lines and de-energizing the catenary system. Safety Given the difficulty of accessing the roof, the Elios 3 provided a safe way to collect data without risking staff or passengers. It allowed for remote inspections in areas that were otherwise inaccessible. Speed Data collection was carried out at night when fewer trains and people were around, making the environment safer. The task was completed in just two flight sessions, significantly reducing the time required for the inspection. Delays in railway transport can be frustrating for passengers and costly for businesses. When cargo trains are delayed, entire supply chains can be affected, causing ripples far beyond the original point of disruption. Ensuring the smooth operation of train stations and their infrastructure is therefore crucial. Inspecting structures like the roof of a train station is particularly challenging when trains are running. So, what’s the solution? The answer lies in technology—specifically, drones like the Elios 3. These devices offer a safe, efficient, and non-disruptive alternative to traditional inspection methods.

Vortex Hardware & Maintenance BV, a Dutch drone and robotics specialist and Flyability partner, has collaborated with NS Stations on multiple maintenance projects across various railway sites. They’ve successfully completed several proof-of-concept inspections of railway station infrastructure, ranging from modern to historic buildings. At one specific station, there was concern about the condition of metal beams in the roof. Built in the early 1900s, the structure made it difficult to access the space between the beams and the roof for inspection. Without scaffolding, which would have disrupted train operations, the team needed an alternative solution. The Elios 3 provided a safe and effective way to gather critical data without any operational interruptions. Sep Schetters and Remco Bunder of NS Stations had previously worked with Ruben of Vortex, so they knew the Elios 3 could handle this project. The Elios 2 had already been used to inspect a pedestrian bridge, proving its effectiveness in complex environments. Now, the team was ready to tackle the more challenging task of inspecting a train station roof.

For this particular station, the team planned to use the Elios 3’s LiDAR payload to accurately locate defects and anomalies. In collaboration with NS Stations and ProRail, they conducted ground-based LiDAR scans to plan the drone flights safely. This helped them comply with regulations that restrict drone flights near people and trains. They scheduled the inspection for nighttime when fewer trains and people were present, ensuring a safer environment. Additionally, since the site was near a large airport, they coordinated with Air Traffic Control to ensure all flights adhered to safety protocols. Using LiDAR, the team mapped the entire space between the roof, cables, and metal beams. With the Elios 2, Ruben did initial reconnaissance before flying the Elios 3 on a pre-planned route. He focused on areas of concern while conducting a general review of the structure. A construction adviser was on-site to guide the data collection by pointing out key areas. The main challenge was ensuring no flights occurred while trains were moving through the station. Two observers on the platform monitored the area and communicated with Ruben via radio to alert him of incoming trains.

Traditionally, such inspections required scaffolding and significant downtime, with 3 train lines closed and the catenary voltage turned off. This process was slow, inefficient, and offered limited visibility. Using the Elios 3, however, the team was able to gather accurate data quickly and without disrupting daily operations.

The risks associated with the inspection were greatly reduced using the Elios 3. Its built-in lighting system, producing 16,000 lumens, ensured clear visibility even at night. The drone’s adaptability and ability to navigate tight spaces made it the ideal tool for this complex task. Vortex and NS Stations were already confident in the use of drones for inspections. This project took their capabilities to the next level, offering unprecedented situational awareness while keeping everyone safe. Unlike traditional methods, the Elios 3 allowed for targeted maintenance without shutting down the entire station. This approach saved millions in costs by avoiding full-scale renovations and reduced the need for extensive planning. It also improved efficiency by providing accurate data for future maintenance tasks. ProRail praised the use of the Elios 3, calling it a game-changer that offers flexibility, reduces inconvenience, and improves asset inspection accuracy.

As railway managers move towards more proactive maintenance strategies, the Elios 3 provides a powerful tool for real-time monitoring and decision-making. With 3D data accessible from a computer screen, teams can now assess assets more accurately than ever before. Discover more about the Elios 3 and its applications in infrastructure inspections today. 200kg/h Potato Chips Production Line 200Kg/H Potato Chips Production Line,Automatic French Fries Equipment,Frozen French Fries Processing Line,Baked Potato Chips Production Line Zhucheng Lijie Food Machinery Co., Ltd. , https://www.lijiegroup.comEliminating Downtime for a Train Station Roof Inspection with Elios Drones

Key Benefits at a Glance

The Elios 3 has already inspected a railway bridge — but what about a train station?

Customer Needs: Accessing the Roof Structure of a Train Station

Solution: Inspecting a Train Station with the Elios 3

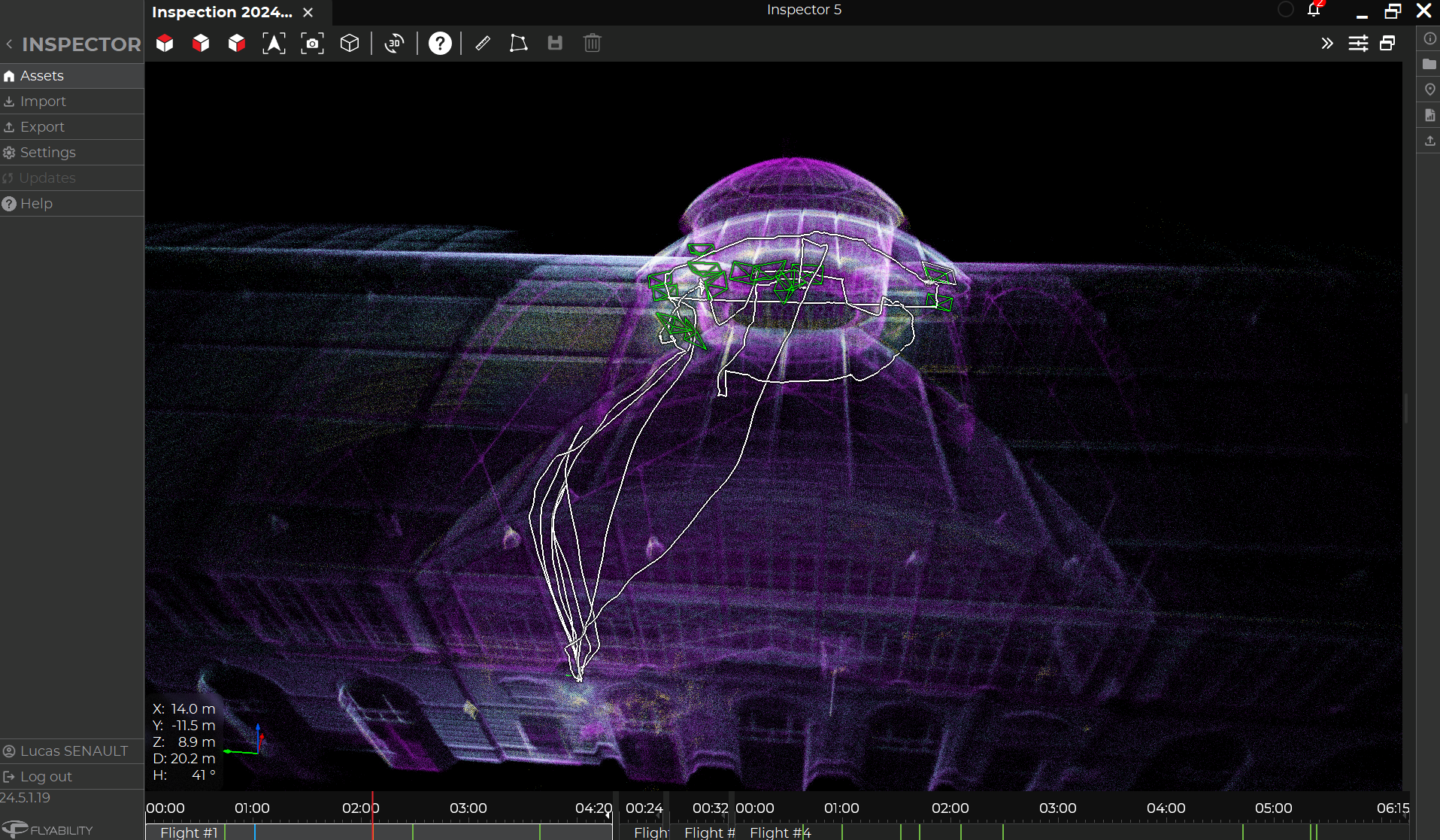

The LiDAR scan of the train station with the Elios 3 captured complex structures, including this protruding element in the roof

Results: Flying the Elios 3 at Night

The Elios 3 flew at night around the station to gather data — can you spot it in the photo?

The Benefits of the Elios 3 Drone for Infrastructure Inspections

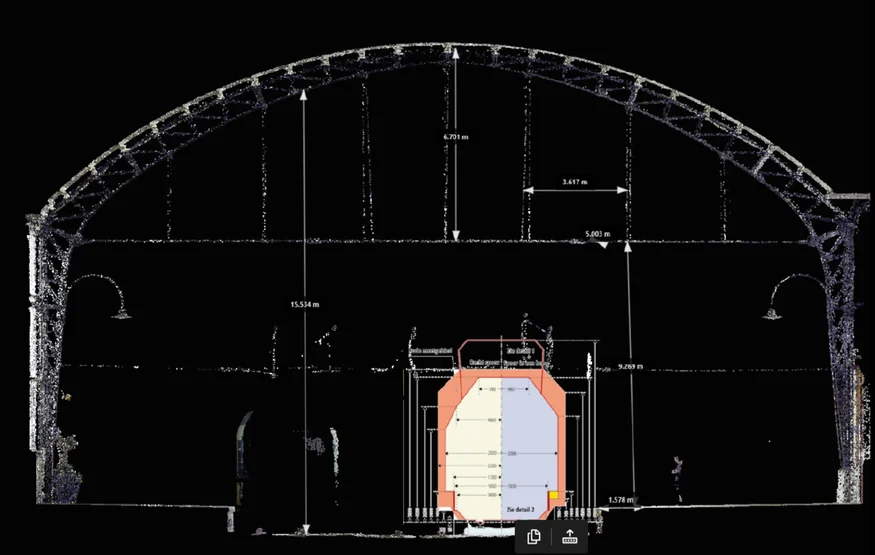

The entire building structure could be visualized with the LiDAR point cloud, along with distance measurements

The Elios 3 in Future Railway Infrastructure Inspections

The Elios 3 saved weeks of work, unnecessary work at height, and did not disrupt rail traffic