With the need to avoid any disruption to train operations, an inspection team in the Netherlands turned to the Elios 3 drone to inspect the roof of a busy train station. Access Due to the complex structure of the train station, traditional inspections were not feasible without significant disruptions. With the Elios 3, the team was able to gather detailed data during nighttime operations, avoiding the need for scheduled train downtime that could take up to 13 weeks to plan. No Downtime The Elios 3 allowed inspections to be conducted without interrupting rail services. This meant no changes to public transport schedules and no need to shut down three train lines or de-energize the catenary system as was previously required. Safety The station's structure made it dangerous for workers to access the roof directly. The Elios 3 provided a safe and efficient way to collect critical data without risking staff safety or disturbing passengers. Speed By flying at night when fewer trains and people were around, the inspection was completed in just two flight sessions, significantly reducing the time needed compared to traditional methods. Unplanned delays on railways can cause major inconvenience for travelers and disrupt supply chains. Maintaining railway infrastructure is essential to ensure smooth operations. However, inspecting structures like train station roofs while trains are running can be challenging. So, how do you safely and efficiently check these areas? That’s where the Elios 3 comes in. It offers a smart, safe, and effective solution for inspecting hard-to-reach places without disrupting daily operations. Vortex Hardware & Maintenance BV, a Dutch partner of Flyability, has been working with NS Stations on various maintenance projects across the country. One particular station had concerns about the condition of its metal roof beams, built in the early 1900s. Traditional inspection methods would require scaffolding, which would disrupt train operations. Without accurate data, maintenance work was based on assumptions, leading to inefficiencies. The Elios 3 offered a safe and practical solution to inspect the roof without affecting daily operations. Experienced in using drones for infrastructure inspections, the team from Vortex and NS Stations knew the Elios 3 could handle this task. The Elios 3’s LiDAR payload allowed for precise mapping of the roof structure, including hidden elements and cable locations. To comply with safety regulations, they used a ground-based LiDAR scanner to plan the drone’s flight path. They also coordinated with Air Traffic Control due to the proximity of a nearby airport and conducted flights at night to minimize interference with train traffic and crowds. During the inspection, a construction adviser was on-site to guide data collection. The team ensured no flights occurred while trains were passing by, using observers on the platform to communicate with the drone operator. Using LiDAR, the team mapped the entire structure, identifying potential issues with high precision. The Elios 3 flew a pre-planned route, collecting data in areas of concern and conducting a general review of the station’s roof. This approach eliminated the need for scaffolding, reduced risks, and avoided any disruption to train services. Traditional inspections required extensive planning, closure of train lines, and significant resources. With the Elios 3, the process became faster, safer, and more cost-effective. The drone’s powerful lighting system made night flights possible, and its ability to navigate tight spaces made it ideal for complex environments. This project demonstrated the potential of drones in revolutionizing infrastructure inspections, making them more efficient and less disruptive. Vortex and NS Stations have long been advocates of drone technology. This project further proved the value of drones in maintaining railway infrastructure. By providing real-time 3D data, the Elios 3 allows for proactive maintenance, reducing the need for full-scale renovations and saving millions in costs. ProRail praised the use of the Elios 3, stating it offers greater flexibility, reduces the need for scaffolding, and improves site awareness. With this technology, railway managers can now make informed decisions based on real-time data rather than estimates. Discover more about the Elios 3 and its applications in infrastructure inspections today. 100kg/h Sweet Potato Chips Making Machine 100Kg/H Sweet Potato Chips Making Machine,Sweet Poato Chips Pocessing Machine,Sweet Potato Chips Fryer,Sweet Potato Chips Production Line Zhucheng Lijie Food Machinery Co., Ltd. , https://www.lijiegroup.comEliminating Downtime for a Train Station Roof Inspection with Elios Drones

Key Benefits at a Glance

The Elios 3 has already inspected a railway bridge – but what about a train station?Customer Needs: Inspecting a Train Station Roof

Solution: Using the Elios 3 for Station Inspections

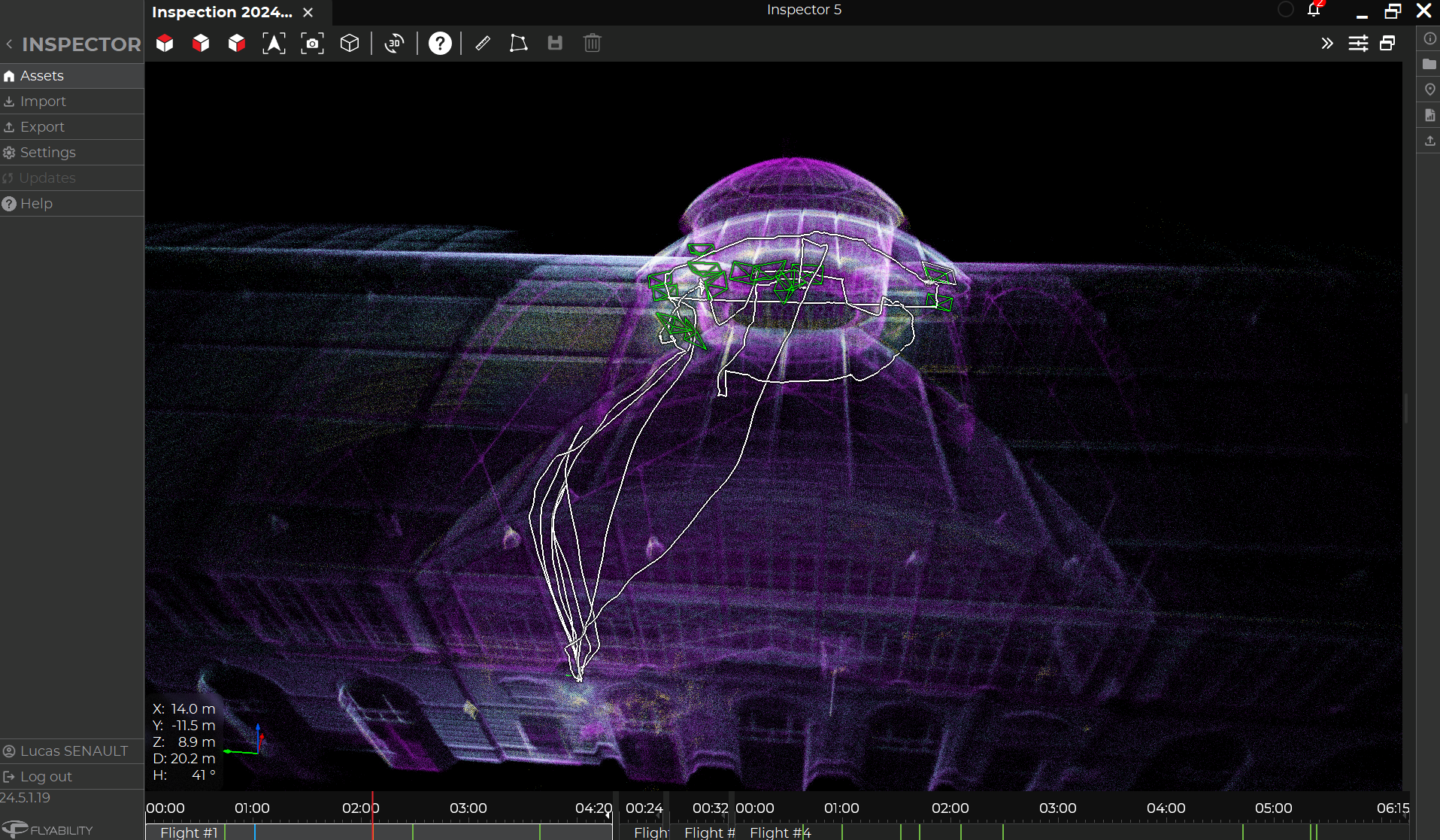

The LiDAR scan of the train station with the Elios 3 captured complex structures, including protruding elements in the roofResults: Efficient and Safe Nighttime Inspection

The Elios 3 flew at night around the station to gather data – can you spot it in the photo?Why the Elios 3 is a Game-Changer

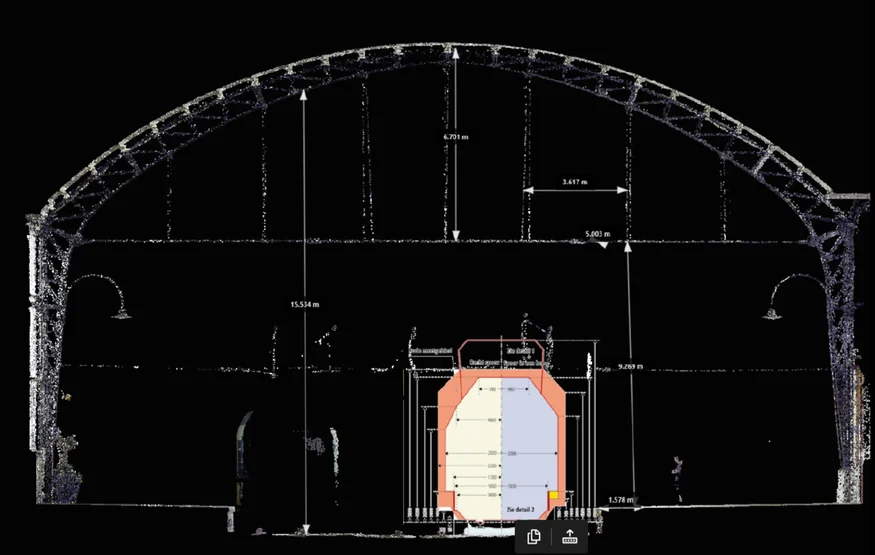

The entire building structure could be visualized with the LiDAR point cloud, along with distance measurementsThe Future of Railway Infrastructure Inspections

The Elios 3 saved weeks of work, unnecessary work at height, and did not disrupt rail traffic