The structure of this type of mould is relatively complex, making it difficult to remove some plastic parts such as caps and closures with detailed threads using standard knock-off methods. After the parts are moulded, they need to be carefully unscrewed from the mould to avoid damaging the threads. With over 15 years of experience in unscrewing moulding, we specialize in Inside Unscrewing Mould, Outside unscrewing mould, and unscrewing mould inside and outside. Therefore, we can design excellent unscrewing moulds to produce various unscrewing products. According to the types of different unscrewing products, we will choose two different demoulding methods: the first one is to use the elastic deformation of the material to forcibly eject the plastic part from the core through the unloading plate when the material allows, which is called Forced demoulding method. The other type is for plastic parts with deeper unscrewing, higher material strength, and higher thread accuracy requirements. We will use the rotational demoulding method. unscrewing injection mold design,auto unscrewing mould,unscrewing injection mould,injection mold unscrewing,Unscrewing Moulds Dongguan Hongke Plastic Precision Mould Co.,Limited , https://www.hongkemold.com

Before the pandemic, businesses worldwide were already turning to automation to address the skill shortages plaguing numerous industries. When the pandemic hit, it accelerated digital transformation, pushing many organizations to adopt automation to manage remote workforces and address safety concerns. This shift sparked debates about the role of automation—does it replace workers whose roles can easily be automated, or does it provide opportunities for them to enhance their skills, collaborate with machines, and engage in more meaningful work?

### Autodesk Launches Global Research Program Exploring the Future of Work

To delve deeper into this topic, Autodesk plans to release several research reports this summer. These studies will explore the state of automation, skills development, and the future of work across various industries and regions. The first report, titled *"The Future of Work is Now: Is APAC Ready?"*, is now available.

> [Read the full report here.](#)

Autodesk believes that automation creates opportunities, but only if workers are equipped with the necessary skills to thrive in an automated world. This includes implementing new credentialing and certification programs, fostering partnerships between public and private sectors to prioritize workforce development, and more.

### State of Preparedness in APAC

APAC is home to 60% of the global workforce and some of the world's largest developing economies. To better understand the labor markets most vulnerable to technological disruption in APAC, the Autodesk Foundation collaborated with Deloitte. Together, they aim to propose solutions to ensure workforces can flourish as automation becomes a reality.

While automation will undoubtedly bring change, the preparedness of countries and industries will determine whether they reap its benefits. Every worker will feel the impact of digitization and automation to some degree. But which industries and countries are best equipped to handle this transition?

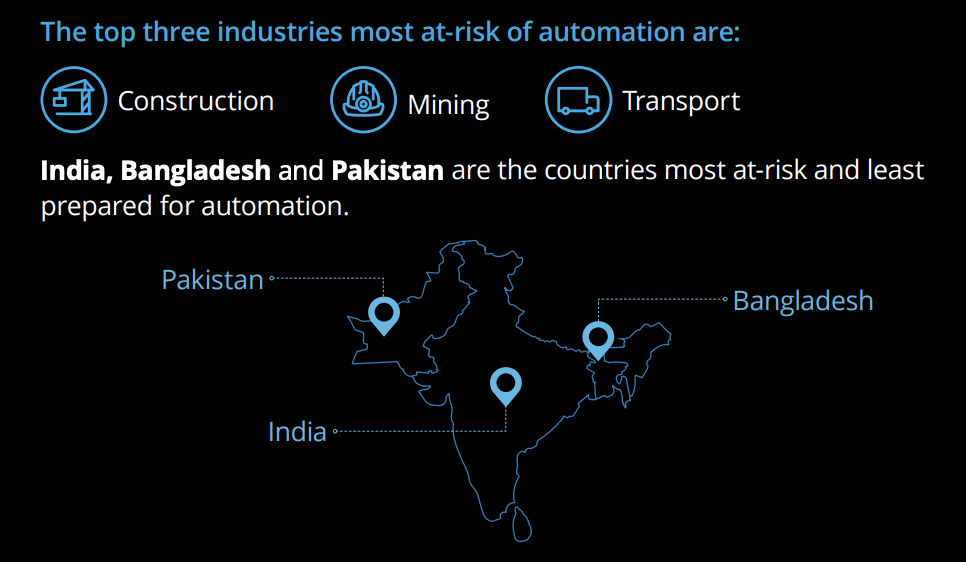

According to the report, not all industries are equally prepared to capitalize on automation. Sectors heavily reliant on routine, manual tasks, like construction, face the highest risk of disruption. Mining, manufacturing, and transportation in APAC also face similar challenges.

Regional preparedness is often tied to economic development. This means countries with the greatest potential for disruption are also the least prepared. For instance, nations like India, Bangladesh, and Pakistan are most at-risk and least prepared for automation. On the other hand, Singapore, Australia, Japan, and South Korea are better positioned to seize the opportunities automation presents.

All countries can take steps to help workers facing automation risks. It's never too early to start preparing, and even small actions can make a difference.

### Taking Proactive Steps to Address Automation Risks

The report outlines several proactive measures to maximize the benefits of automation while minimizing risks:

1. **Increase Awareness:** Shift the narrative away from job losses toward the opportunities for higher-value activities that automation can create.

2. **Fund Industry-Specific Programs:** Support smaller businesses in adopting digital technologies to accelerate automation usage and adoption.

3. **Invest in Learning Programs:** Help disadvantaged workers through reskilling and upskilling programs to build resilience in an ever-changing environment.

This report explores the future of work and automation in 12 APAC countries, including Thailand, Pakistan, India, Bangladesh, Myanmar, Singapore, South Korea, Japan, Vietnam, the Philippines, Indonesia, and Australia.

Despite the diversity of APAC, the report concludes that automation will create opportunities if the right support systems are established and the focus remains on helping workers succeed.

> [Learn more about how Autodesk is committed to helping workers and communities thrive in the age of AI-driven automation.](#)

In 2019, the Autodesk Foundation partnered with Monitor Institute by Deloitte to study the future of work in the U.S., offering insights into closing the skills gap.