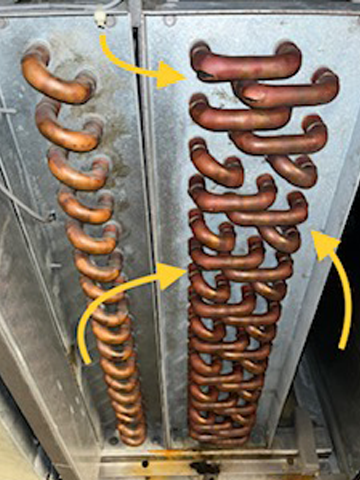

Bundle up, as we go on site with Jack Kessler to assess the all-too-common frozen water coil. Winter is here, and with it comes a flood of service calls about frozen water coils. One recent job at a New York City condo complex brought us to a Dunham-Bush® unit that had suffered serious damage — the water inside had frozen, causing the u-bends to rupture. This particular unit featured a 2-row hot water coil and a 4-row chilled water coil, both using 5/8" copper tubing. The unit was located in an area that relied entirely on outside air, meaning it was the first to be exposed to extreme cold when the dampers were open. Normally, a freeze stat would detect temperatures below 32°F and trigger the dampers to close. Unfortunately, in this case, the freeze stat was faulty, leaving the dampers open and allowing the water to freeze. As water turns into ice, it expands by about 9%, which led to the coil rupturing. To Repair or Replace? That is the Question. In this situation, we opted to replace the entire coil. However, not all cases require a full replacement. In many instances, a damaged coil can be repaired using brazing — a process where two metal pieces are joined by melting a filler metal. Whether you choose repair or replacement depends on several factors: If you're dealing with a water coil or any other type of coil that's showing signs of damage, give us a call. We offer custom and OEM replacement coils for every make, model, and year — whether your coil is frozen or just needs a little TLC.

Acrylic sheet has the reputation of "plastic crystal", And has excellent weather ability, especially used in outdoor, not because of years of weathered, and yellow, and the phenomenon of hydrolysis, the other plastics, and have good surface hardness and gloss, machining plasticity is big, can be made into various shapes and you need products, strong resistance to impact, 16 times as the common glass, suitable for installation in special need security zone, The high recovery rate is recognized by the increasing environmental awareness. Our main production thickness of 20-200mm acrylic one-time casting board, also can produce acrylic superimposed board, superimposed thickness can reach 800mm, can accept customization, acrylic board using Lucite monomer production, transparency can reach more than 92%, the maximum specification of acrylic board is 9000×3000mm, the minimum size is 1600×2600mm. Acrylic Sheet,Acrylic Glass,Acrylic Board,Acrylic Panels Jiangsu Jinsui Acrylic Technology Co., LTD , https://www.jinsuiacrylic.comSite Bite: Ruptured U-Bends in a Frozen Water Coil

Written by: Jack Kessler

Intern, Nationwide Coils