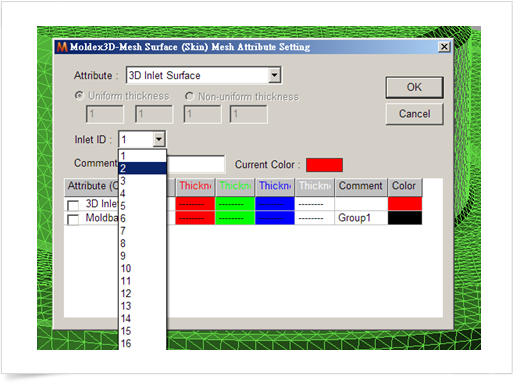

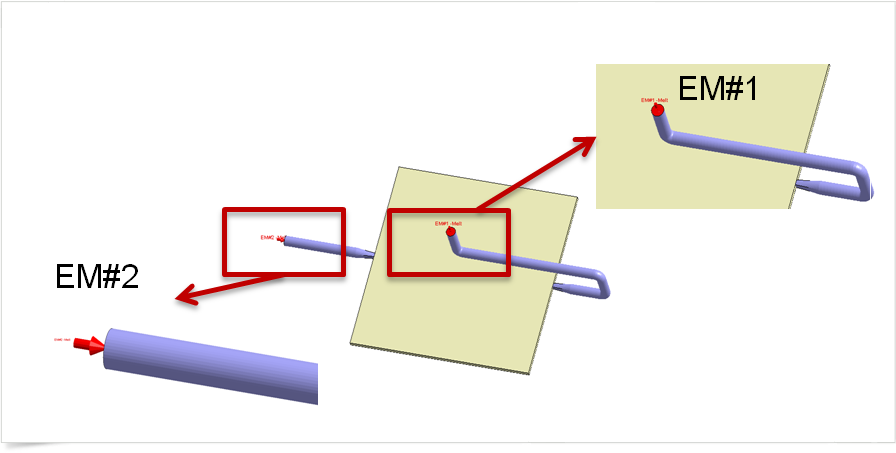

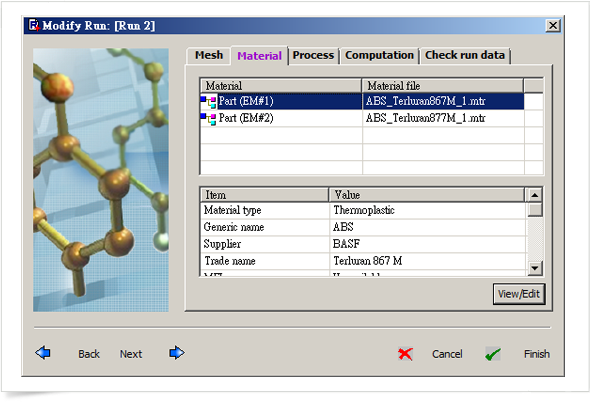

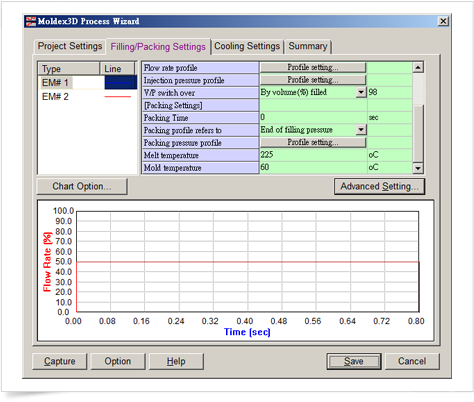

The melt filling for Bi-injection molding is done by two independently controlled barrels. There are two melt entrances from each barrel and each barrel has its own material and flow rate profile. The procedure below details how to assign two melt entrances and their respective material and flow rate in Moldex3D are as follows: 1. During the meshing, assign the first material gate Inlet ID1 and the second one Inlet ID2. 2. During the process setting, assign the first material Part (EM#1), and the second material Part (EM#2). 3. The filling and packing profiles can be decided independently at Filling/Packing setting. 4. The post-processing display can show the flow rate for each material.  Compared with the traditional polishing process breakthrough 1. plasma can penetrate the narrow slits, dead corners, and other parts of the jewelry that are hard to reach by traditional mechanical polishing, especially suitable for openwork and inlay jewelry. 2. Ordinary jewelry can be polished in 2-3 minutes, the efficiency is more than 10 times manual polishing. For example, the traditional manual polishing of small hardware daily handling capacity of about 100 pieces, while the plasma jewelry polishing equipment can handle more than 100 pieces per minute. 3. Applicable materials: gold, K gold, silver, and more. Plasma jewelry polishing machine provides subversive polishing solutions for jewelry processing industry. Jewelry Polishing Machine,Jewelry Polisher,jewelry polishing equipment,Polishing Machine Jewelry,jewellery polishing machine​ Dongguan Bayi Automation Equipment Co., Ltd , https://www.bayiautomation.com

Bi-Injection Demo

Bi-Injection Demo

Professional Jewelry Polishing Machine

A highly efficient polishing machine developed for precious metals and complex-shaped jewelry.